View as PDF

American National Standard for Continuous Hinges

This Standard establishes requirements for architectural continuous hinges used in building construction. Cycle, abuse, overload, vertical wear, and strength tests are included. For further information, consult the full standard, ANSI/BHMA A156.26 for Continuous Hinges.

BHMA has created this series of Hardware Highlights to provide useful, accessible information about builders hardware for anyone with an interest in devices that hang, control, secure, and trim the doors. BHMA is the trade association which represents almost all of the North American manufacturers of builders hardware. One of its main activities since 1983 has been the development and maintenance of ANSI-approved standards for many separate product categories.

Product Performance: Purchasers of hardware certified to A156.26 (https://buildershardware.com/CertificationProgram/Certified-Products-Directory) can be assured products will perform to their expectations.

Below are an explanation and some examples of the evaluations conducted for certification:

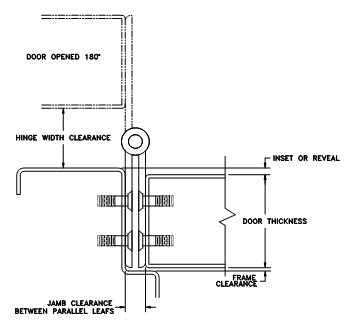

The standard contains a full set of terminology relating to continuous hinges. Definitions such as "Half Edge Mounted. Having one leaf applied to the surface of the butt edge of the door and the other leaf applied to the face of the door frame" helps users to accurately specify and order hinges.

Obviously building products are expected to last a long time and builders hardware is no exception. Grade 1 hinges, for example must pass a rigorous test through 2.5 million cycles of opening and closing on a door of a specified weight.

Hinges may be specified with additional safety and security features as needed for the application. The standard defines hospital hinges having sloped barrels, maximum security pins (MSP), and nonremovable pins (NRP), among others.

The reliable closing and sealing of openings can also contribute to energy conservation. BHMA has developed Product Category Rules, which will further define sustainability requirements.

|

Function Numbers and Illustrations

Another significant contribution of standards for product specification is a numbering system for hinge types. Please consult A156.26 for the full list; an example is provided here:

A13021B

Section A, brass/bronze material, full surface hinges, no electrical modifications, for a 300 lb. door, grade 1, barrel hinge.

|

|